Dana Oil Tools delivers high-quality well-completion

equipment and services to the oil and gas industry in Iran and international markets. Dana Oil Tools, a subsidiary of Dana Energy Company

, has recruited skilled and proficient engineers who have substantial years of experience. Our technical designers have mastered the ability to design and manufacture various oil tools including different categories of completions.

Dana Oil Tools provides a comprehensive range of fully integrated completion systems, including equipment, products, processes, procedures, and programs to provide a combination of best-in-class and fit-for-purpose products and services.

Dana Oil Tools has recruited highly skilled professionals in design, manufacturing, quality control and production planning and is ready to supply complete downhole completion equipment of the highest quality. Although the main range of productions of the company is compatible with those of Baker Hughes , Halliburton, Camco, OTIS, Dana Oil Tools is also ready to provide other types of completion equipment in the same class. In order to provide localized and fit-for-purpose production that meets all customer needs, Dana Oil Tools design team is qualified to redesign available productions to acquire specific technical requirements in functioning, strength, and corrosion resistance performance, as well as to preserve consistency and interchangeability with other origin types.

Dana Oil Tools provides a comprehensive range of fully integrated completion systems, including equipment, products, processes, procedures, and programs to provide a combination of best-in-class and fit-for-purpose products and services.

Dana Oil Tools has recruited highly skilled professionals in design, manufacturing, quality control and production planning and is ready to supply complete downhole completion equipment of the highest quality. Although the main range of productions of the company is compatible with those of Baker Hughes , Halliburton, Camco, OTIS, Dana Oil Tools is also ready to provide other types of completion equipment in the same class. In order to provide localized and fit-for-purpose production that meets all customer needs, Dana Oil Tools design team is qualified to redesign available productions to acquire specific technical requirements in functioning, strength, and corrosion resistance performance, as well as to preserve consistency and interchangeability with other origin types.

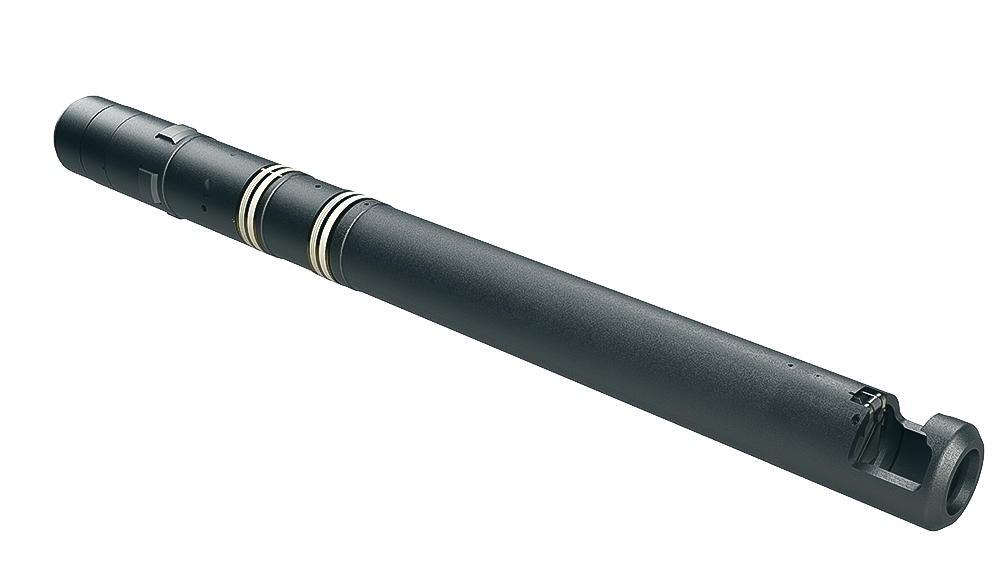

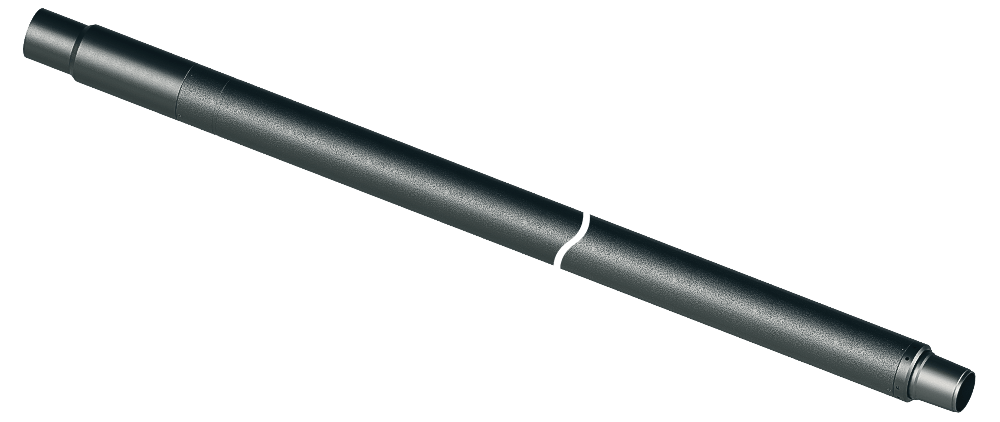

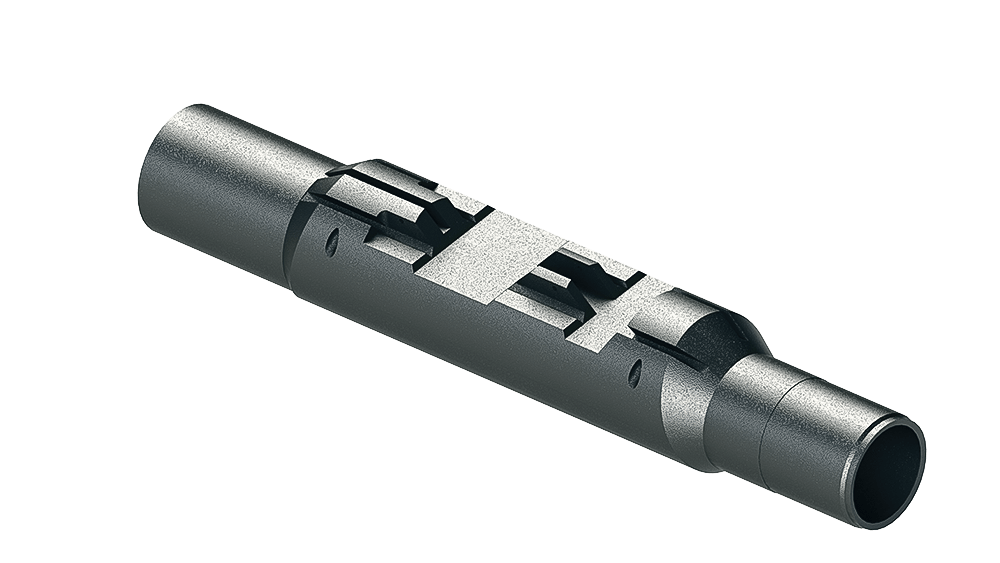

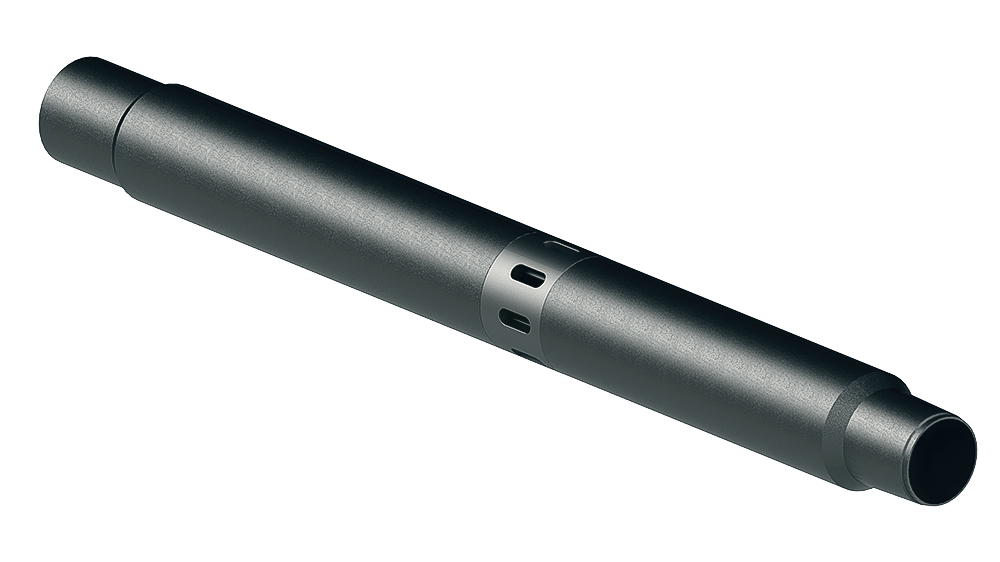

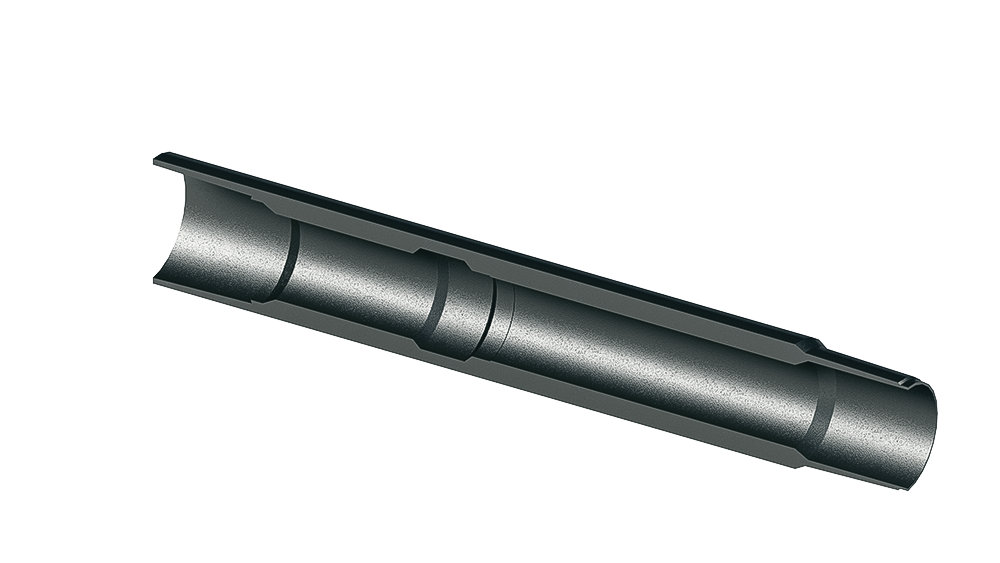

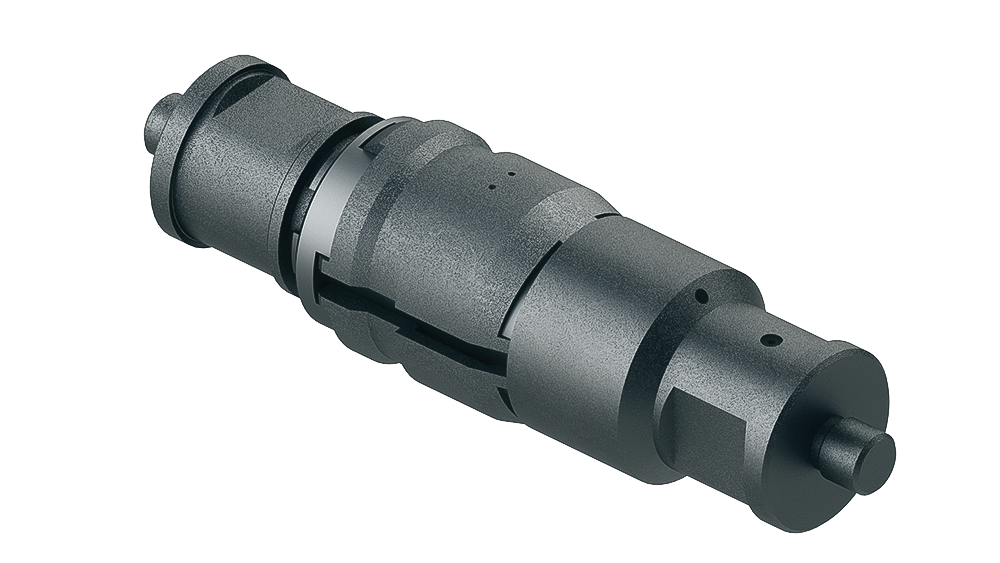

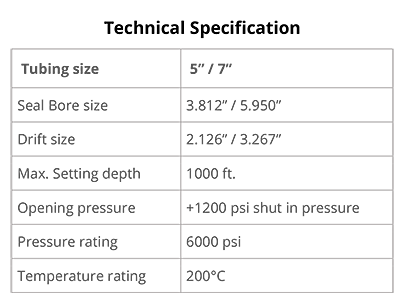

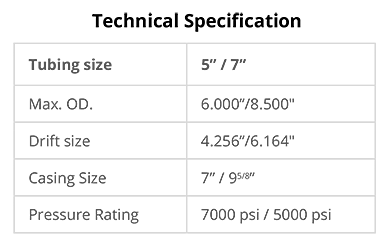

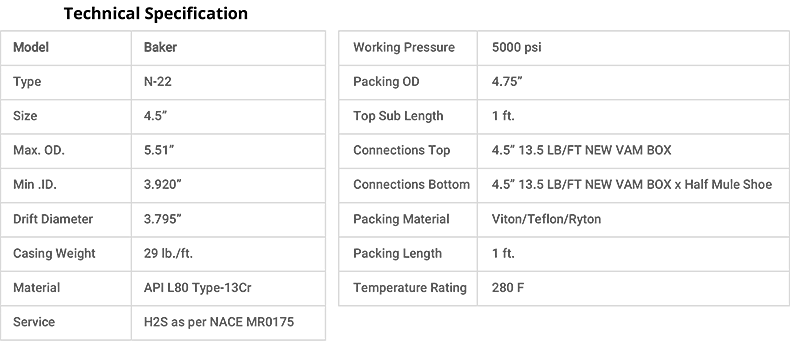

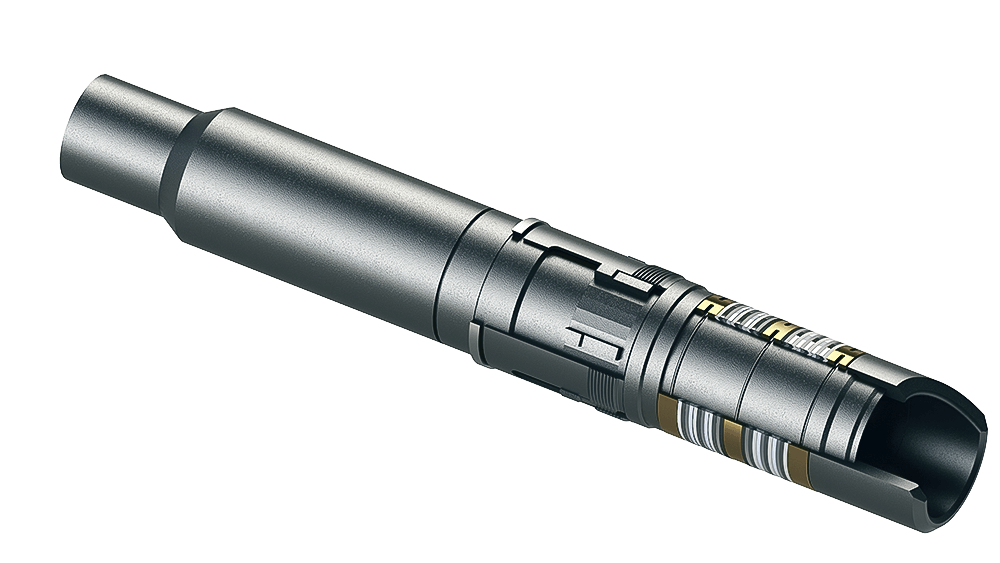

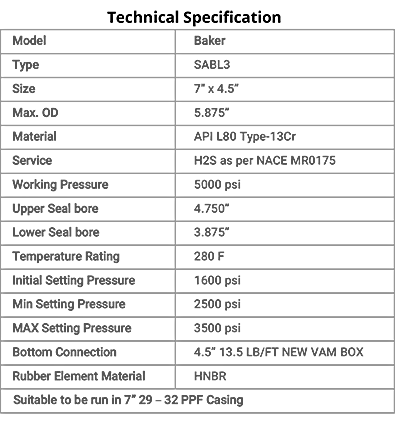

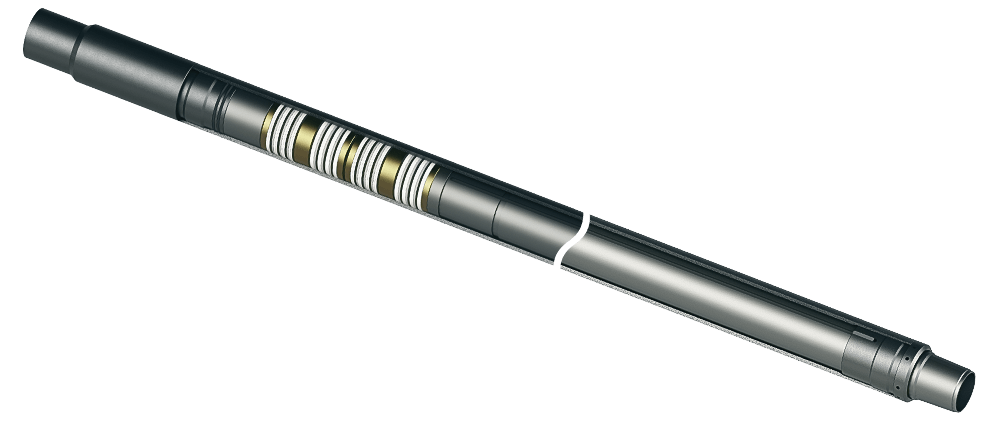

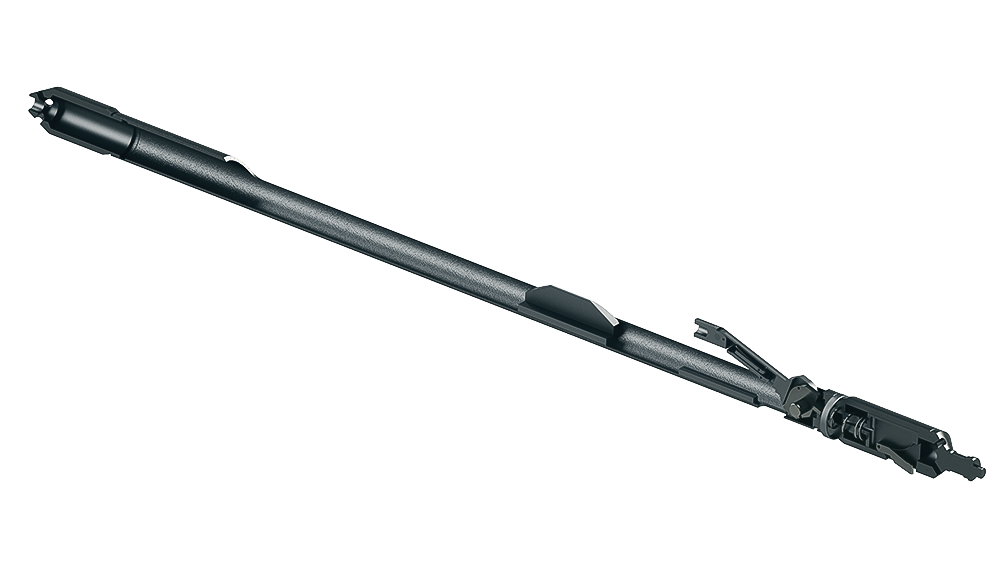

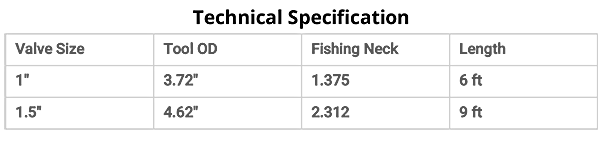

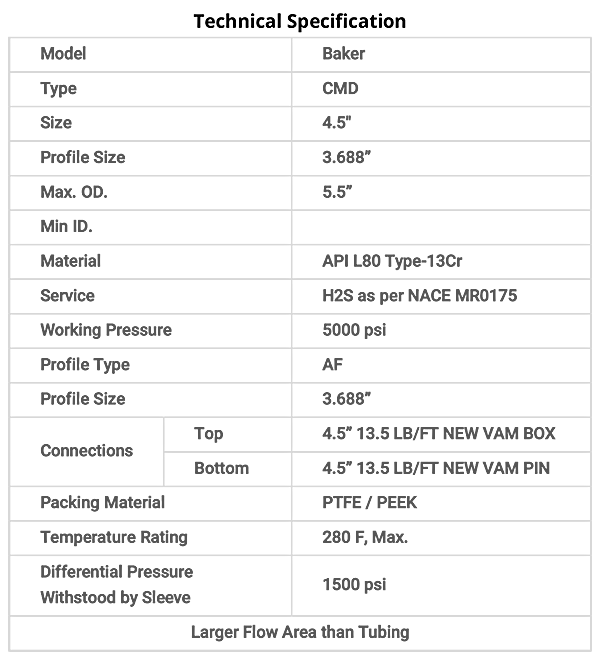

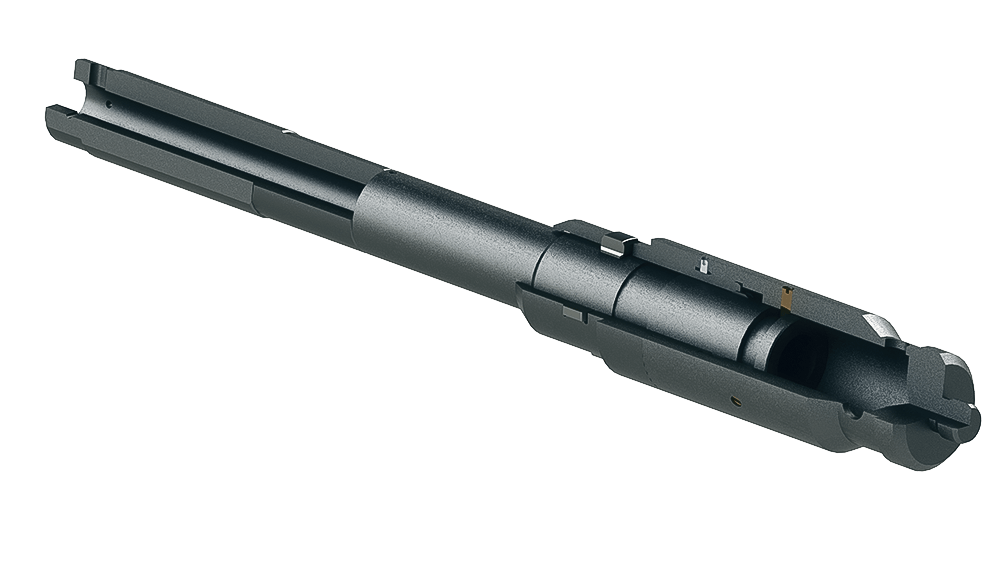

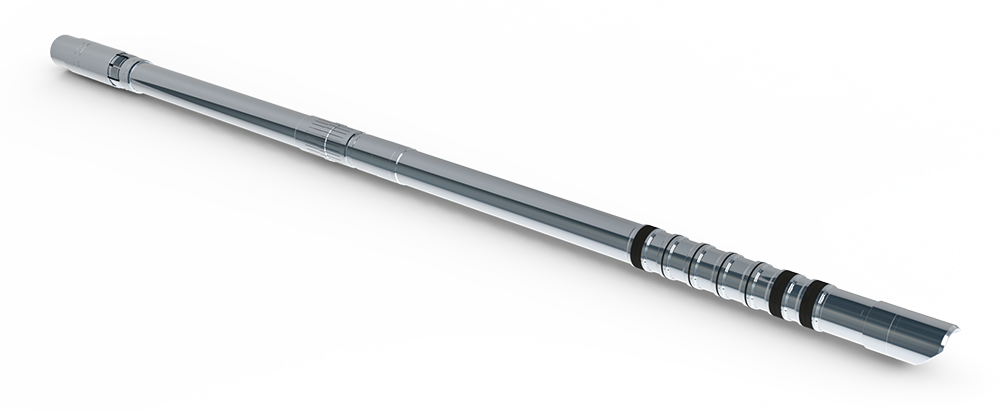

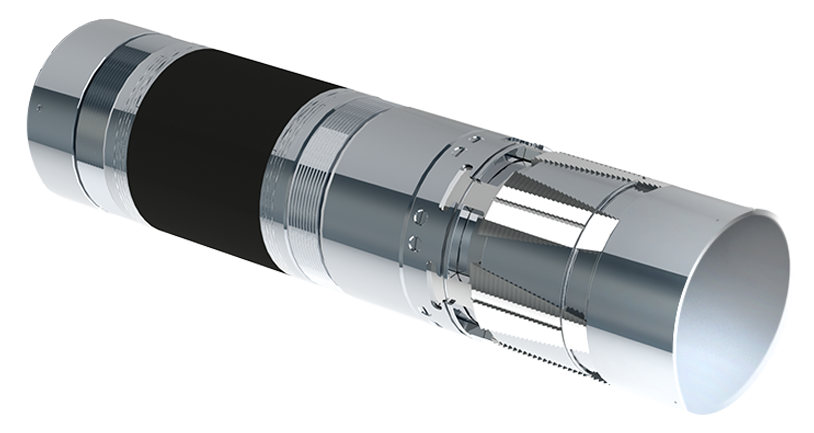

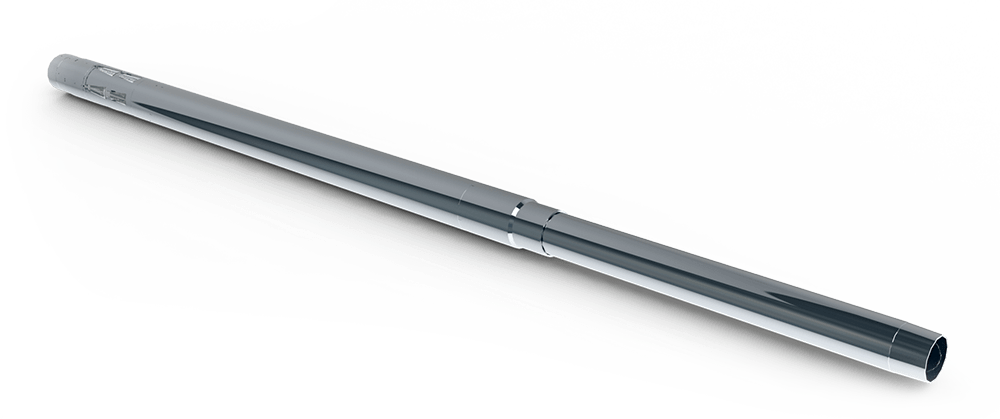

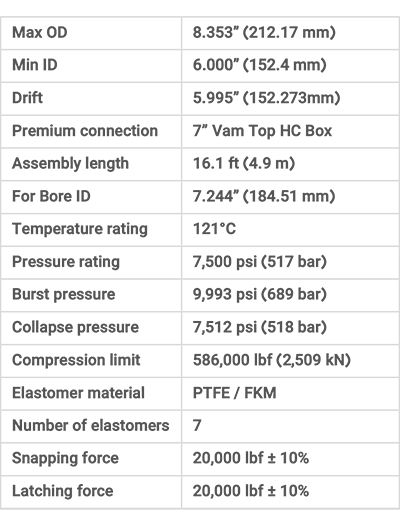

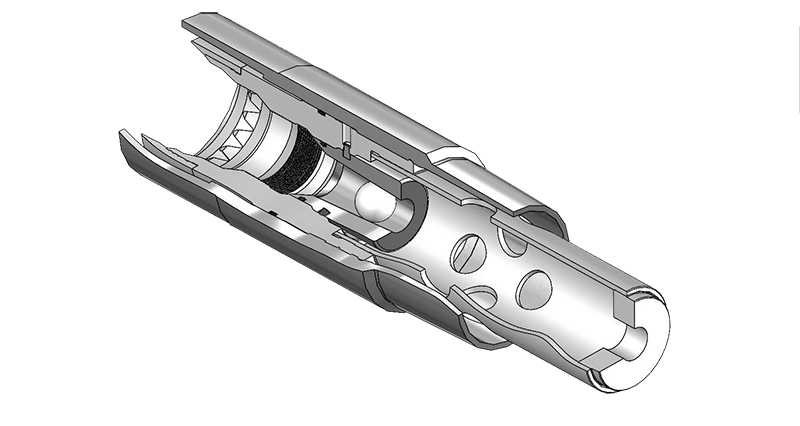

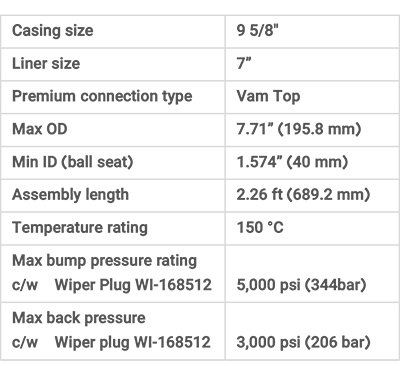

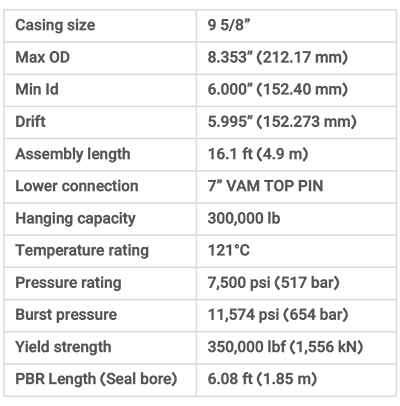

MONOBORE D.H.C SYSTEM

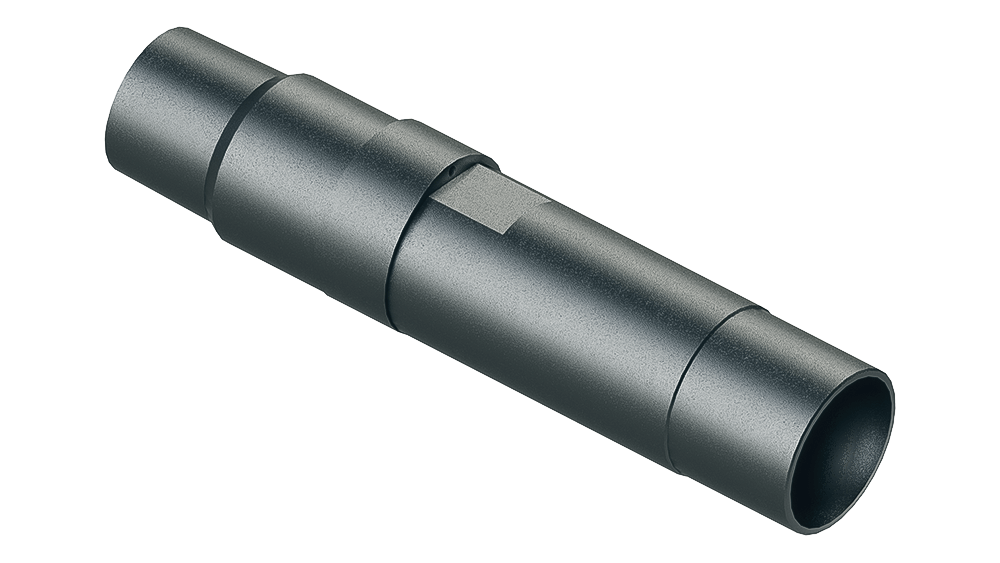

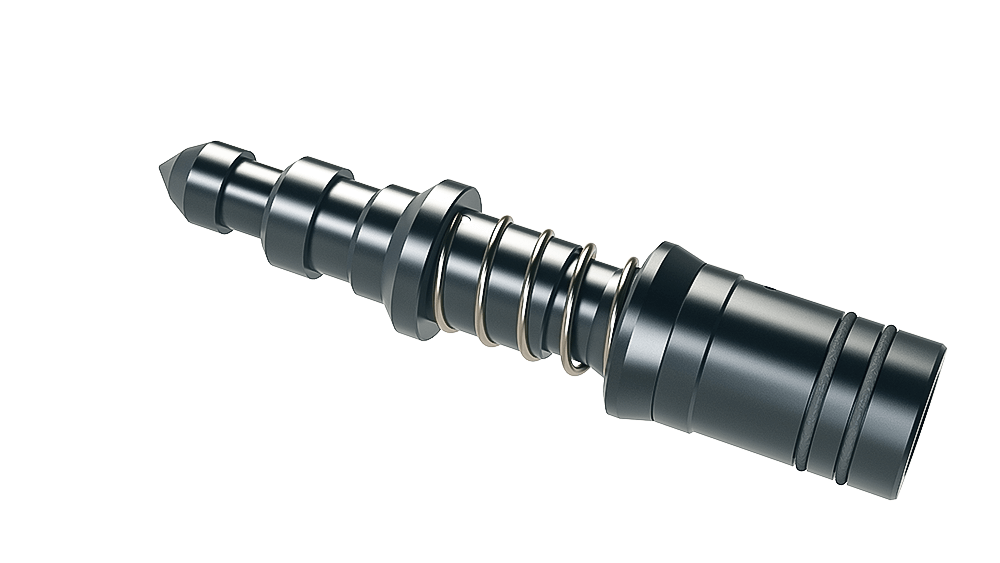

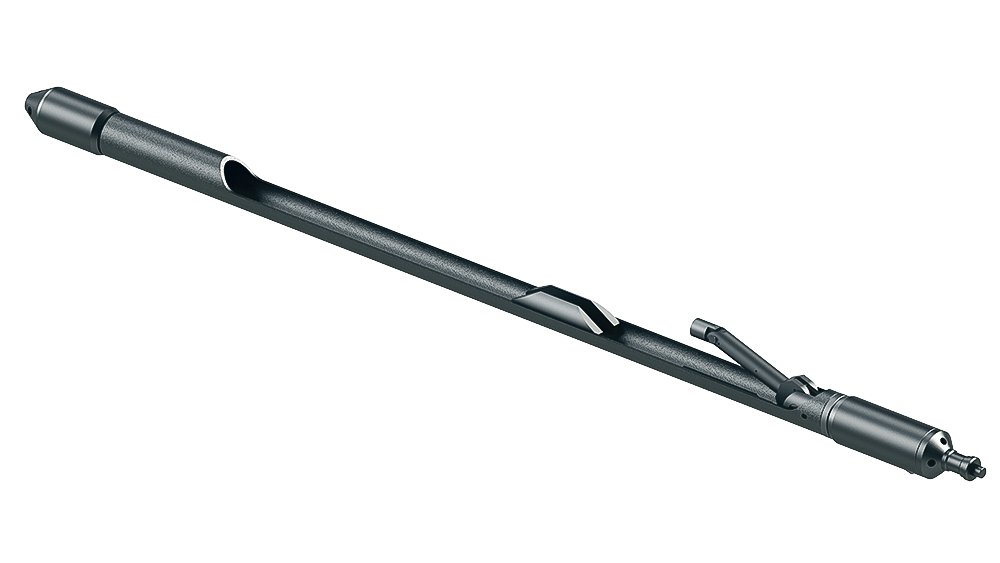

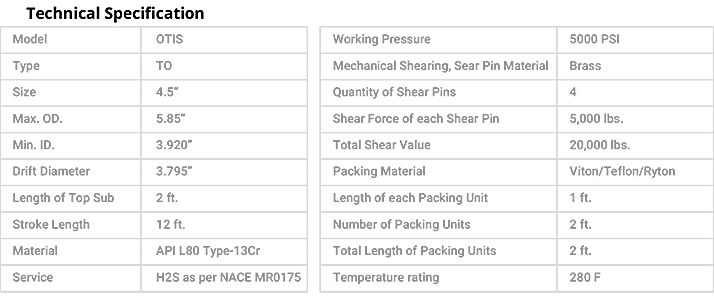

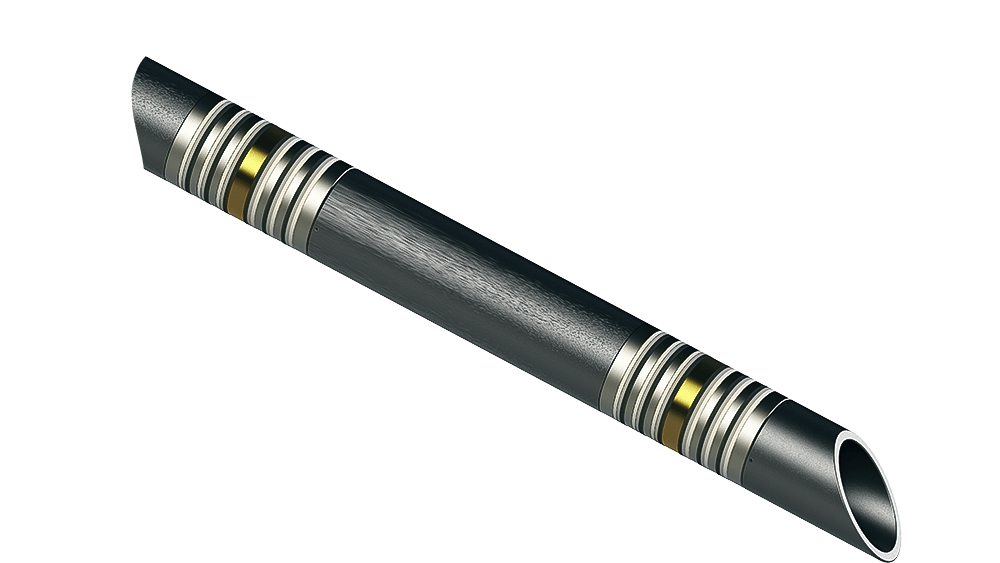

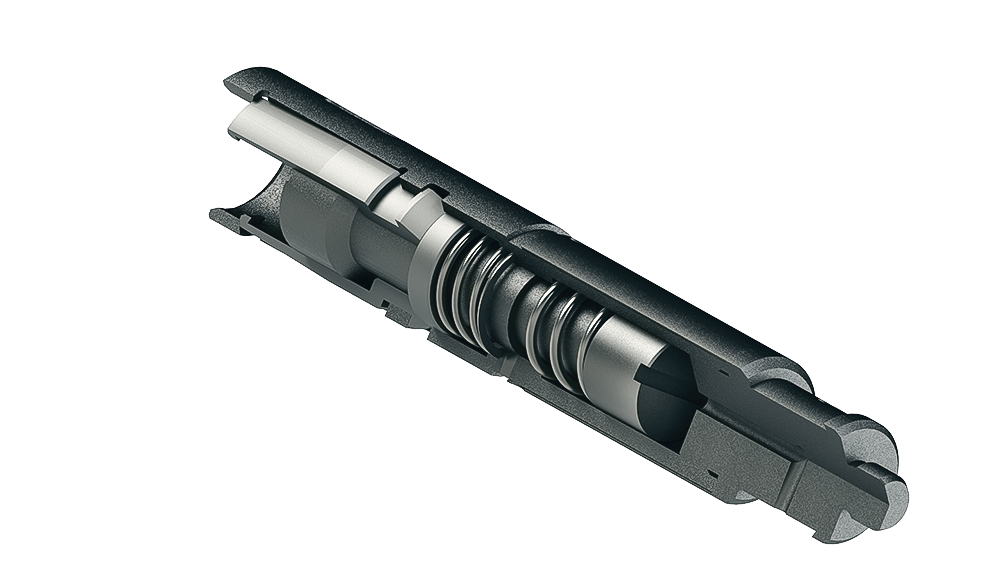

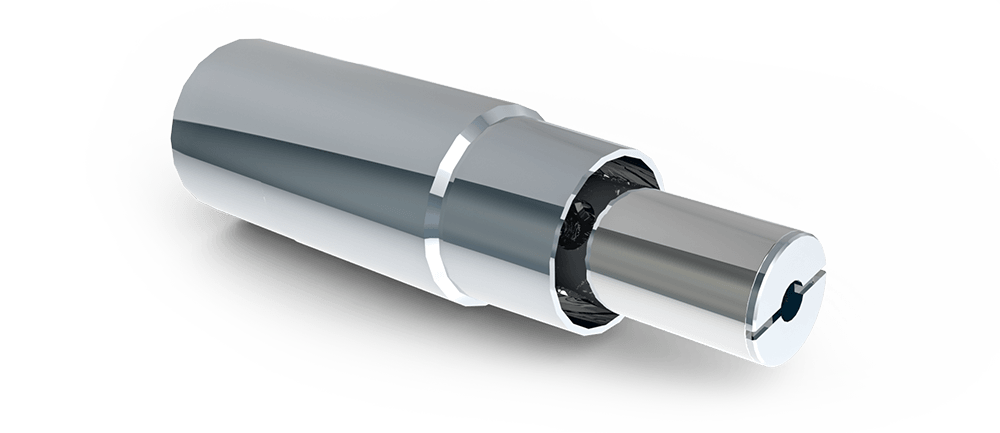

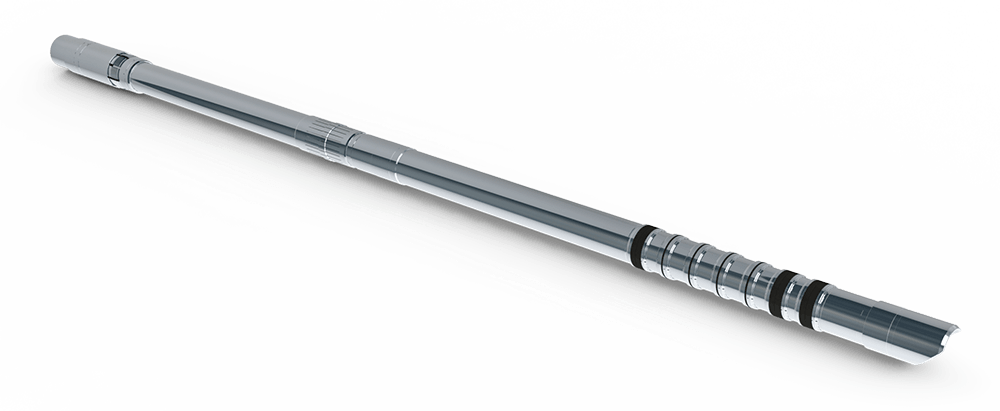

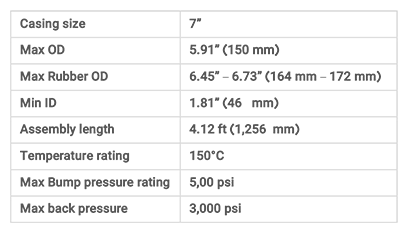

TELESCOPIC D.H.C SYSTEM

OUR CERTIFICATE